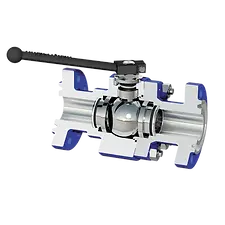

Ball valves

High-Performance metallic sealing gastight ball valves for severe service applications

Designed to individual customer requirements, Hartmann ball valves guarantee the highest levels of safety and availability – even under extreme operating conditions. As a reliable shut-off valve, they resist aggressive media, extreme pressures and temperatures or frequent actuating operations. The metal-to-metal sealing between ball and seat rings with high quality hardfacing provides an especially long service life and minimises maintenance requirements.

The ball valves are equipped with hand lever or gearbox for manual operation. Automatic operation by means of electric, pneumatic or hydraulic actuators. Configuration variants e.g. rapid close, fail-safe-open, fail-safe close and high cycle with ≥200,000 actuations per year. We develop tailor made solutions for special process requirements.

Products / Design

Shut-off ball valves with trunnion mounted ball (type AST) or floating ball (type ASF)

Pigging valves also as replacement for scraper launching systems for measurements, cleaning and separation of media

Ball valves with integrated components such as strainer or non-return valve

Twin ball valves with multiple barriers in pressure direction and cavity pressure bleed off for increased safety requirements

Multi-way ball valves for diversion and changeover units

Heating jacket ball valves for media requiring an increased temperature (e.g. sulphur)

Flow Control ball valves with linear or equal percentage flow characteristic

Drill string ball valves such as Kelly valves and IBOP

Top entry ball valves

Stem extensions for high or low temperature applications or for valve insulation

High pressure ball valves e.g. with BASF lens ring gasket flanges

Nominal bore: DN8 (1/4“) to DN1000 (40“)

Pressure: Vacuum up to 1.035 bar (15,000 psi)

Temperature: -200 °C (-328 °F) to + 550 °C (1022 °F)

Sealing system: Metal-to-metal sealing

Material: Carbon Steel, Stainless Steel, Duplex, Superduplex, Hastelloy, Incolloy, Inconel, Monel, Titanium

Functions: Double block and bleed (DBB), double isolation and bleed (DIB 1 and DIB 2)

Regulations and Standards: API 6A, API 6D, ASME, PED, DGRL, DIN ISO

Certified for: Fire Safe, TA Luft, SIL and more

Connections: Flange, but weld, socket weld, threaded

Media

Crude oil, natural gas, acid gas, syngas, oxygen, hydrogen, helium, steam, thermal water, coal dust, slurry, slag and ash, polymers, cellulose, miscellaneous solids (also corrosive /abrasive), ethylene, liquid sulphur, PE / PP

Ball valves

Type shock

AST - Spherical ball

Gate valve

API 6A ball valves

ASF - Floating ball

Scraper valve

TBV - Twin ball valve

Ball valves for oxygen

Special ball valves

Ball valves for hydrogen

Datasheet

Installation Guide

Rheonik RHE 28 Installation Guide (english)

Rheonik RHE 28 Installation Guide (german)

Wiring diagrams

HART - as Standard Two plus HART

Standard Two - 2*4/20mA (a/p), 2*Pulse/Freq, 2*DO, 2*DI, RS485 (Modbus)

Standard One - 1*4/20mA (a/p), 2*DO (Pulse/Freq/Status), 1*DI, RS485 (Modbus)

Premium - as Standard Two plus HART and analogue input