Ball valves for oxygen

Ball valves for oxygen

Under ambient conditions oxygen is a colorless, odorless gas. It is not flammable, but promotes combustion. The air contains 21 vol% oxygen. Already small amounts of higher oxygen rates increase the burn rate significantly. This can lead to fire ignition of materials. With increased oxygen concentrations, there is an increased risk of fire and explosion!

Especially during opening and closing operations of valves high speeds can occur. At high oxygen concentrations, this can lead to the ignition of plant parts if impurities of any kind are present in the valve together with unsuitable materials or lubricants.

The three essential points in the production of oxygen valves

In order to prevent ignitions within the plant, three essential points must be observed in the manufacture of oxygen fittings.

1. Selection of oxygen-suitable metallic materials

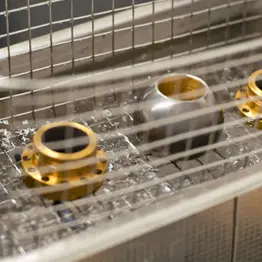

The media-contacted parts must be made of metallic materials suitable for oxygen. When selecting suitable materials, we follow the IGC oxygen standard of the European EIGA. This standard indicates, that carbon and stainless steels may no longer be used at higher pressures, but only special so-called “exempt materials”. Therefore we produce these ball valves from brass or monel and inconel (at higher temperatures). Alternatively, we grade up standard materials such as carbon and stainless steels with innovative welded-on corrosion protection layers, examples of which are nickel plating or copper plating.

2. Selection of suitable sealing materials

The sealing materials must be carefully selected when manufacturing oxygen valves. The sealing materials used at Hartmann have all been approved by the German Federal Office for Materials Research (BAM) in regard to oxygen burnout safety for the related pressure and temperature range.

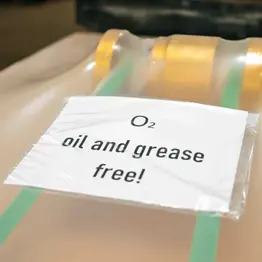

3. Ensuring oil and grease free production

Already natural grease like from our hands may be sufficient to cause ignition of materials in oxygen environment. Therefore, we have strict rules for the production of the valves, which are fixed in our oxygen work instruction, such as ultrasonic cleaning and the assembly and testing of the fittings in a separate oxygen room. In addition, only special lubricants suitable for oxygen are used in very small amounts during assembly, and the leak test that follows is carried out exclusively with gas. After successful testing, the oxygen ball valves will be packed in welded foil and separately marked to indicate that they are free of oil and grease.

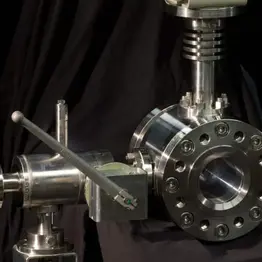

Hartmann ball valves for oxygen

We develop and manufacture two-way and multi-way ball valves for oxygen applications. By choosing the right design and following important regulations when manufacturing our oxygen valves, we can contribute to safe operation when shutting off oxygen plants, even at high temperatures and pressures.

Our oxygen ball valves are used when standard valves reach their limits. Hartmann’s oxygen valves therefore fulfill the following criteria:

Use of materials suitable for oxygen

Suitability for higher pressure ranges up to 420 bar and more

Suitability for high temperature ranges up to 550°C

Under ambient conditions oxygen is a colorless, odorless gas. It is not flammable, but promotes combustion. The air contains 21 vol% oxygen. Already small amounts of higher oxygen rates increase the burn rate significantly. This can lead to fire ignition of materials. With increased oxygen concentrations, there is an increased risk of fire and explosion!

Especially during opening and closing operations of valves high speeds can occur. At high oxygen concentrations, this can lead to the ignition of plant parts if impurities of any kind are present in the valve together with unsuitable materials or lubricants.

The three essential points in the production of oxygen valves

In order to prevent ignitions within the plant, three essential points must be observed in the manufacture of oxygen fittings.

1. Selection of oxygen-suitable metallic materials

The media-contacted parts must be made of metallic materials suitable for oxygen. When selecting suitable materials, we follow the IGC oxygen standard of the European EIGA. This standard indicates, that carbon and stainless steels may no longer be used at higher pressures, but only special so-called “exempt materials”. Therefore we produce these ball valves from brass or monel and inconel (at higher temperatures). Alternatively, we grade up standard materials such as carbon and stainless steels with innovative welded-on corrosion protection layers, examples of which are nickel plating or copper plating.

2. Selection of suitable sealing materials

The sealing materials must be carefully selected when manufacturing oxygen valves. The sealing materials used at Hartmann have all been approved by the German Federal Office for Materials Research (BAM) in regard to oxygen burnout safety for the related pressure and temperature range.

3. Ensuring oil and grease free production

Already natural grease like from our hands may be sufficient to cause ignition of materials in oxygen environment. Therefore, we have strict rules for the production of the valves, which are fixed in our oxygen work instruction, such as ultrasonic cleaning and the assembly and testing of the fittings in a separate oxygen room. In addition, only special lubricants suitable for oxygen are used in very small amounts during assembly, and the leak test that follows is carried out exclusively with gas. After successful testing, the oxygen ball valves will be packed in welded foil and separately marked to indicate that they are free of oil and grease.

Hartmann ball valves for oxygen

We develop and manufacture two-way and multi-way ball valves for oxygen applications. By choosing the right design and following important regulations when manufacturing our oxygen valves, we can contribute to safe operation when shutting off oxygen plants, even at high temperatures and pressures.

Our oxygen ball valves are used when standard valves reach their limits. Hartmann’s oxygen valves therefore fulfill the following criteria:

Use of materials suitable for oxygen

Suitability for higher pressure ranges up to 420 bar and more

Suitability for high temperature ranges up to 550°C

Típusok

Title | Ductile Iron | Denomination | Stainless Steel |

|---|

Heading 2

Heading 2